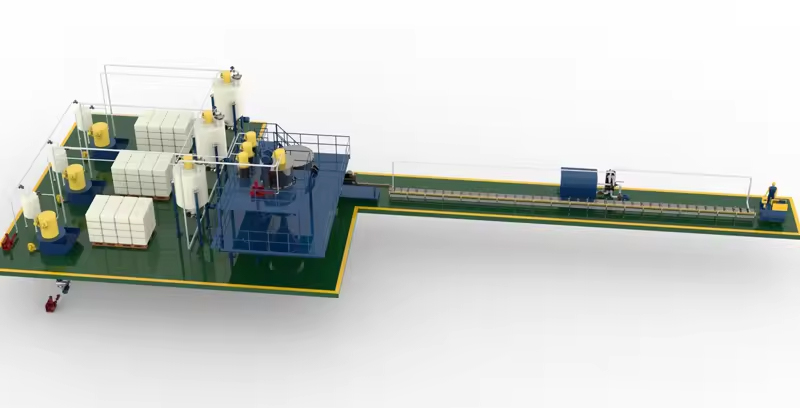

Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

Recently, a customer asked us about the price of a full set of hot melt glue stick production line equipment, and said that under the same production caoacity, there are peers with lower prices than us.

After comparing the equipment parameters, we found that the length of the hot melt glue stick cooling water tank provided by our peers to the customer was not enough to cool the hot melt glue stick well.

Thank the customer for choosing us after fully understanding the situation. At the same time, we would like to disclose to you the "low price trap" of this hot melt glue stick production line.

1. Hot melt glue is not fully cooled and deforms when cutting sticks

If the hot melt glue is still in a semi-soft or high temperature state before cutting, the cut surface is uneven, the sticks are flat, and the edges are sticky, resulting in appearance defects and affecting sales.

2. The surface of the hot melt glue stick is sticky

The cooling is incomplete, and the surface of the glue stick still has residual temperature, which is easy to stick to each other during the collection or packaging process, making it difficult to separate, affecting subsequent use.

3. Glue stick cannot pass through the cutting machine or traction system normally

The overheated softened state will cause the stick to deform and slip, making it difficult to pull stably or cut accurately, and may even cause the machine to jam or break the adhesive.

4. The product has large internal stress and deforms or cracks after storage

If the cooling process is too fast or uneven, stress will be left inside the stick, adn deformation, warping or surface cracking may occur after storage for a perios of time.

5. Hot melt glue stick production line speed is limited and the efficiency is low

In order to compensate for insufficient cooling, the extrusion speed can only be reduced or the residence time can be extended, which reduces the efficiency of the entire production line.