Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

As a manufacturer with 20 years of equipment manufacturing experience, JCT recommends bulk hot melt glue production line to customers who are new to the hot melt glue industry. The main reasons are low investment threshold, simple process, low risk and easy expansion.

1. Equipment configuration is the simplest and process difficulty is low

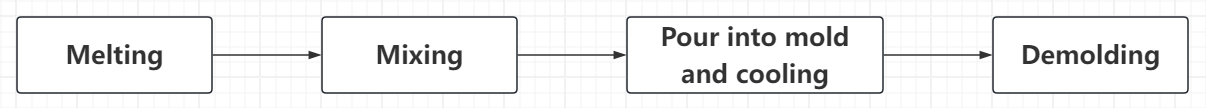

Short production process:

No high-precision equipment (such as underwater granulating system, pillow hot melt glue packaging machine or high speed granulator) is required, only:

No high-precision equipment (such as underwater granulating system, pillow hot melt glue packaging machine or high speed granulator) is required, only:

The process is easy to master, with low requirements for operators, reducing training costs.

2. Suitable for a variety of hot melt glue formulas

One set of equipemtn has multiple uses, and customers can flexibly adjust products according to market demand.

3. Wide market demand and acceptable packaging

Industrial customers (furniture, footwear, packaging industries) have a high acceptance of bulk hot melt glue.

Large package bulk adhesive (10kg-20kg) is easy to transport and store, and is suitable for export.

4. Low investment threshold and low risk

The investment of a small bulk hot melt glue production line is 30%-50% lower than that of a pillow or granule production line.

No automatic packaging system is required, reducing the initial capital pressure.

Suitable for small-scale start-ups, rapid market entry, and avoiding large losses due to unfamiliarity with the industry.