Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

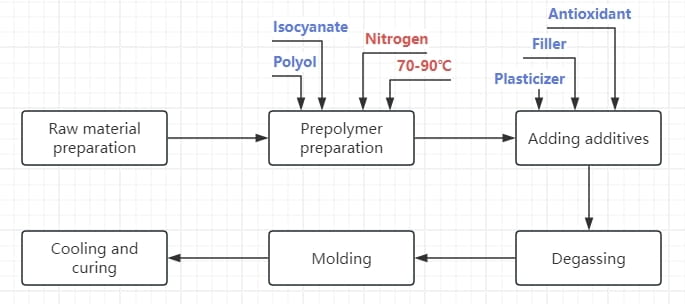

Polyolefin hot melt glue is a kind of hot melt glue with polyolefin resin as the main component. Polyolefin is a kind of polymer material formed by the polymerization of olefin monomers (such as ethylene, propylene, etc.). Due to its excellent performance, polyolefin hot melt glue is widely used in packaging, textiles, automobiles, electronics and other fields.

Product Specification:Polyolefin hot melt glue is a kind of hot melt glue with polyolefin resin as the main component. Polyolefin is a kind of polymer material formed by the polymerization of olefin monomers (such as ethylene, propylene, etc.). Due to its excellent performance, polyolefin hot melt glue is widely used in packaging, textiles, automobiles, electronics and other fields.

1. Highly automated to improve production efficiency

2. Advanced extrusion and mixing processes to ensure uniform dispersion

3. Precise temperature control system to optimize hot melt glue performance

4. Environmentally friendly and energy-saving design to reduce waste emissions

5. Compatible with multiple formulas to meet different application requirements

6. Intelligent monitoring and remote maintenance to reduce maintenance costs

| Ingredients | Functions |

| Polyolefin resins (such as APAO, PB, PE, PP) | Main ingredients, determine the performance of the glue |

| Tackifiers (such as C5/C9 petroleum resin, terpene resin) | Improve bonding strength and wettability |

| Plasticizers (such as mineral oil, EVA) | Adjust viscosity and improve fluidity |

| Antioxidants (such as 1010, 168) | Prevent high temperature degradation and extend life |

| Fillers (such as calcium carbonate, talc) | Reduce costs and adjust performance |

| Wax (such as Fischer-Tropsch wax, microcrystalline wax) | Reduce melt viscosity and improve wetability |

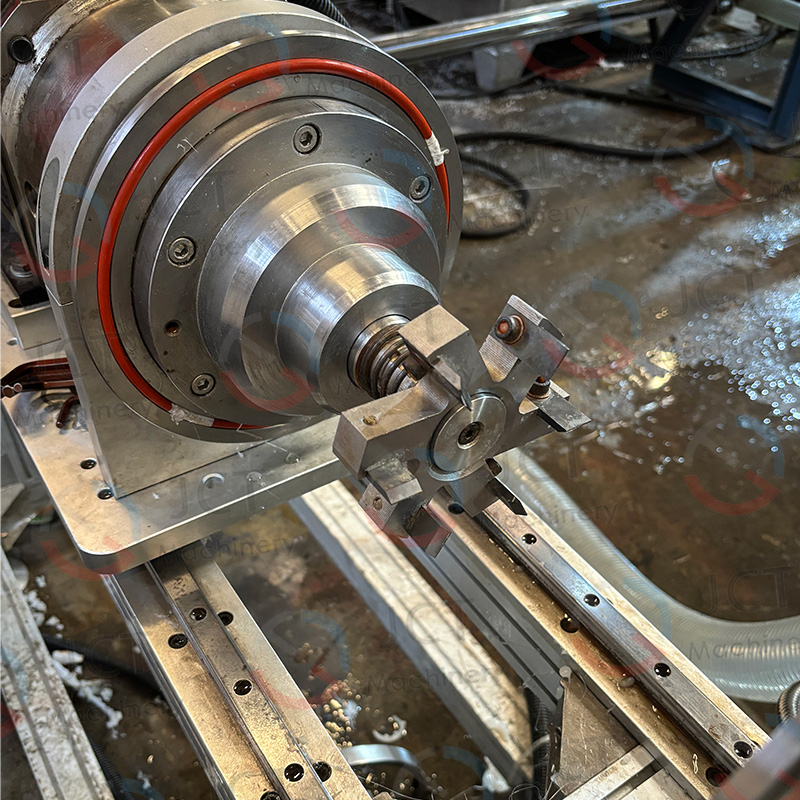

JCT found that some hot melt glue granules produced by some production line equipment on the market have tails (i.e. the granule shape is not smooth enough, and there is a phenomenon of drawing or tailing). Choosing JCT’s equipments can prevent this from happening.

Please provide your requested item product name and request details as like box style, material, dimensions, color and logo request, we can help to find out best packing solution.