Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

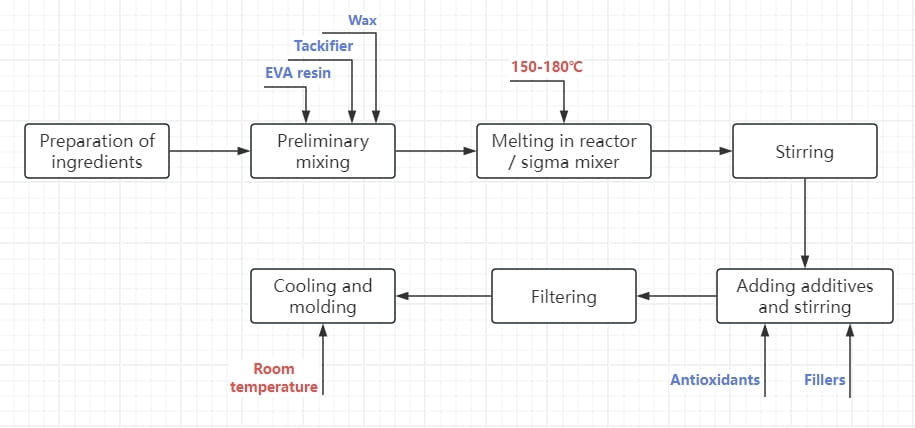

EVA hot melt glue is a solvent-free, water-free, 100% solid fusible polymer. It is solid at room temperature and becomes a flowable liquid adhesive with a certain viscosity when heated and melted to a certain degree. After melting, it is light brown, translucent, or native white.

Product Specification:EVA hot melt glue is a solvent-free, water-free, 100% solid fusible polymer. It is solid at room temperature and becomes a flowable liquid adhesive with a certain viscosity when heated and melted to a certain degree. After melting, it is light brown, translucent, or native white.

| Ingredients | Function |

| EVA resin | Base material, provides viscoelasticity |

| Tackifying resin (such as petroleum resin) | Improve bonding strength and fluidity |

| Wax | Reduce melt viscosity, improve fluidity, control open time |

| Antioxidant | Improve thermal stability, prevent degradation |

| Filler (such as calcium carbonate, silica) | Reduce cost, adjust rheological properties |

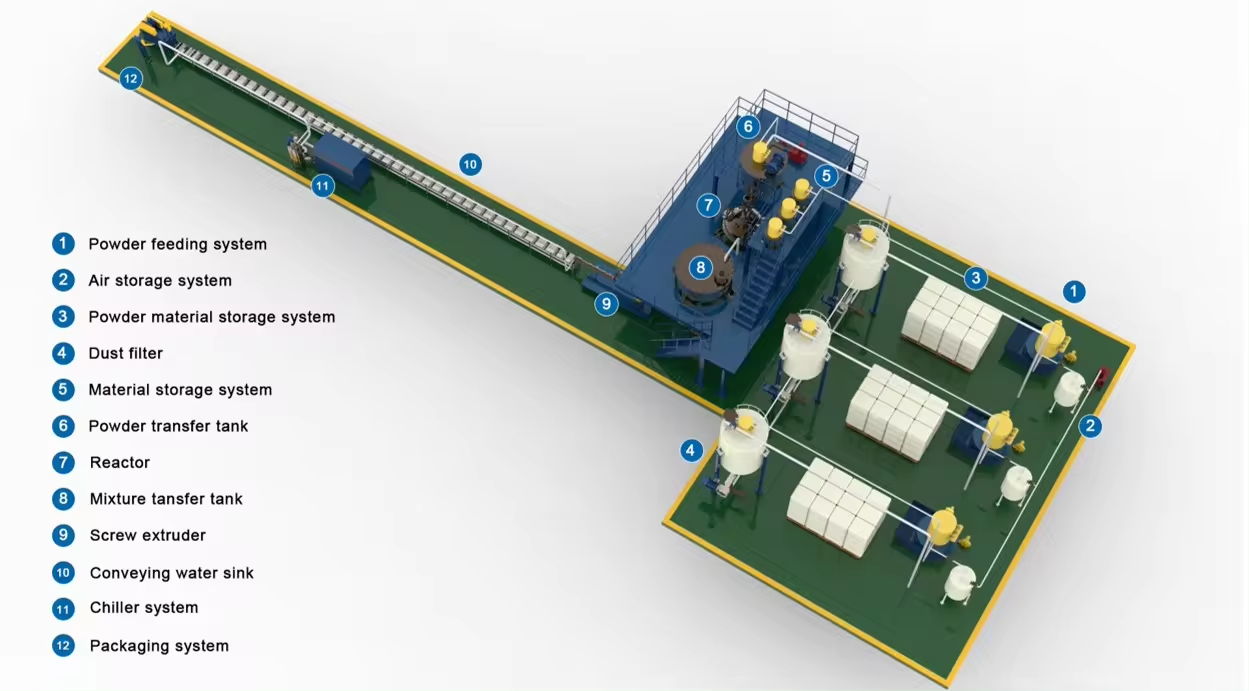

JCT’s stick EVA hot melt glue production line helps customers improve production efficiency, reduce scrap rate, and adapt to diverse market demands with high-precision extrusion, intelligent control, energy-saving design and flexible adaptability.

Please provide your requested item product name and request details as like box style, material, dimensions, color and logo request, we can help to find out best packing solution.