Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

Hot melt glue stick is solid adhesive that come in stick or bar form at room temperature and require heating and melting with a hot melt glue gun before use. It is primarily used for:

| 100kg/h | 200kg/h | 300kg/h |

| 500kg/h | 1000kg/h | 1500kg/h |

| Can be designed according to the capacity of the demand side | ||

1. Raw material proportion

Main raw materials: EVA, resin (such as rosin-modified resin), wax, antioxidant.

Adjust the ratio based on viscosity, flexibility, initial tack and other requirements.

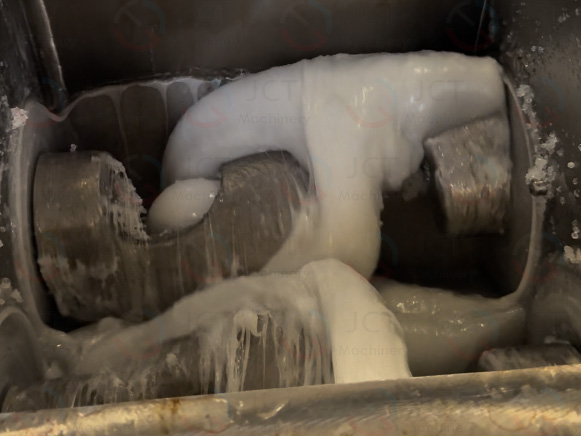

2. Melt mixing

Add materials → Heat to melt → Mix untial uniform

3. Extrusion

The hot material is extruded through the extruder die into sticks.

4. Cooling and shaping

A cooling water tank or air cooling system allows for rapid curing of the hot melt glue sticks.

5. Cutting and packaging

Cut to length using a cutting machine.

Automatic packaging machine/manual packaging of finished products.

1. Extrusion Pressure and Speed Control

Constant screw speed: Utilizes variable frequency control or servo drive to maintain a stable screw speed and avoid flow fluctuations.

High-precision die design: Die diameter to lerance is less than ±0.05mm, and the finish is highly polished, minimizing friction and uneven material flow.

Adjustable back pressure: Adjusting back pressure stabilizes material density, preventing hollowness or uneven diameters in the rubber stick.

2. Consistent Cooling and Shaping

Uniform cooling rate: The cooling water temperature and flow rate are consistent to avoid oval sticks caused by excessive cooling in one diraction and slow cooling in the other.

Guiding device: A guide wheel or bracket is installed within the cooling trough to prevent the hot melt glue sticks from drifting and bending.

Shaping length: The cooling length is sufficient. After existing the trough, the hot melt glue sticks must be completely solidified before being cut.

3. Cutting and Inspection

Cut-to-length machine: Utilizes a servo-controlled cutter with an accuracy controllable to ±0.5mm.

In-line diameter gauge (optional): Installed after cooling, a laser diameter measurement device measures the diameter of the hot melt glue stick in real time and provides feedback to the extruder for speed adjustment.

Surface inspection: A visual inspection system can be added to remove hot melt glue with bubbles, cracks and abnormal color.