Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

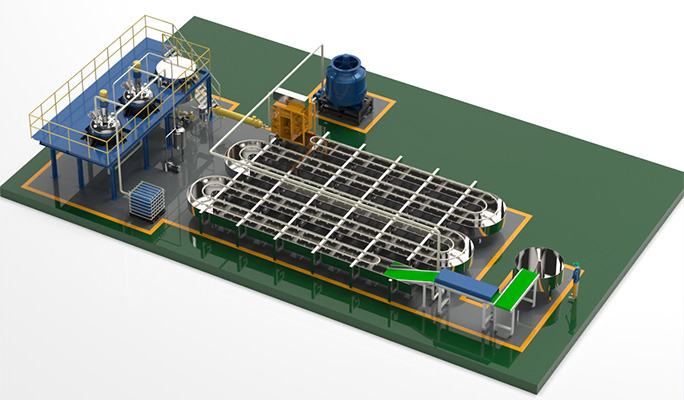

1. Raw Material Feeding System

Equipped with automatic metering and feeding (vacuum loader/screw loader), reducing manual labor.

Precise error control makes it suitable for large-scale continuous production.

2. Reaction Mixing Equipment

Fully automated with PLC control, it automatically adjusts temperature, pressure and stirring speed.

Equipped with data monitoring and recording functions to ensure formula consistency.

3. Molding System

Fully automated underwater/srafece granulating, stick extrusion, pillow packaging, with automatic cutting and cooling.

High production efficiency and uniform finised product particle size.

4. Packaging System

Equipped withautomatic weighing and automatic packaging (bags/boxes).

Unmanned operation is possible, reducing labor.

5. Control System

Centralized PLC + touch screen control enables one-touch start and stop, fully automated process flow.

1. Raw Material Feeding

Most of these processes are done manually, requiring weighing and a low level of automation.

2. Reaction Mixing Equipment

Controls are manual or semi-automatic. Some equipment can set temperature and stirring, but manual monitoring is required.

3. Molding System

Bulk hot melt glue production lin typically requires manual placement of the molding die.

4. Packaging System

Primarily manual weighing and packaging, suitable for low-volume factories.

5. Control System

Decentralized control, with numerous operational steps, requires the involvement of skilled workers.

JCT is professional hot melt glue production line turnkey project provider, including glue formula, complete set of equipment, after-sales services, etc.

We can customize a hot melt glue production line that suits you according to your budget requirements, feel free to contact us: +86-181 3837 3963 (Whatsapp, Wechat) or jctmixing@outlook.com.