With the continuous development of the global automotive industry, especially the rapid growth of new energy vehicles and smart cars, the demand for automotive adhesives has also risen. Among the many adhesives, SBC (styrene block copolymer) system hot melt pressure sensitive adhesive is rapidly becoming one of the irreplaceable materials in the automotive field due to its excellent flexibility, adhesion and low VOC environmental performance.

Why does the automotive industry need SBC hot melt pressure sensitive adhesive?

- Wire harness fixing tape: SBC adhesive tape is resistant to high and low temperatures and fatigue, and is an ideal choice for automotive wiring harnesses.

- Interior decoration fixing: Used to fix door panels, seat fabrics, car screens and other components.

- Promoted by environmental protection trends: SBC hot melt adhesive is solvent-free and low-emission, meeting the environmental protection regulations of various countries.

Under this trend, seizing the initiative in SBC hot melt adhesive production is an excellent opportunity for chemical and adhesive companies to expand their high value-added products.

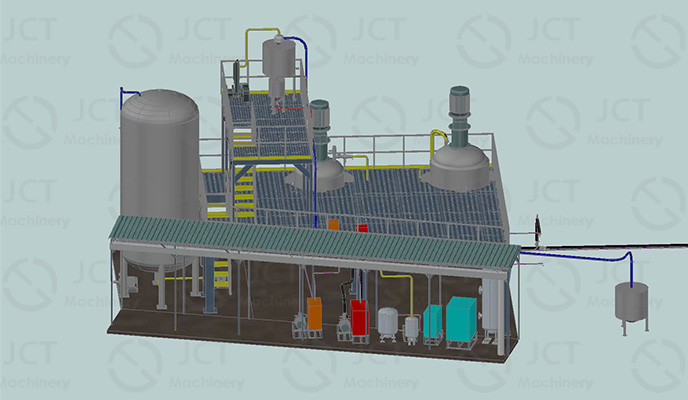

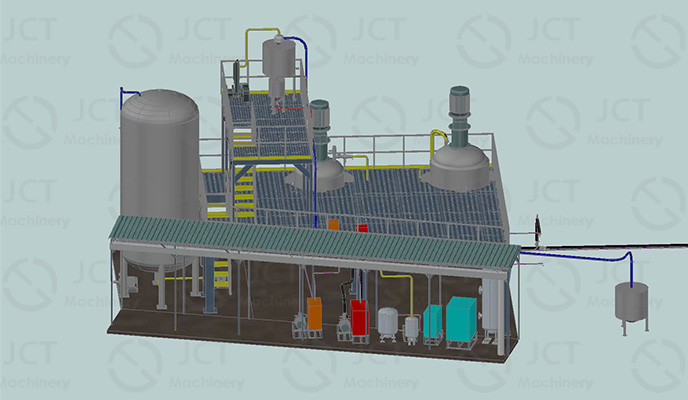

As a chemical mixing equipment manufacturer with more than 20 years of experience, JCT provide one-stop SBC system hot melt pressure sensitive adhesive production line equipment services, including:

- Strong kneading reactor: Suitable for high viscosity, elastomer base material mixing.

- High shear dispersion equipment: To ensure the uniform funsion of resin, white oil and SBC.

- Fully automatic metering and feeding system: To improve production efficiency and accuracy.

- High precision temperature control system: To ensure hot melt glue stability and batch consistency.

- Discharging cooling mold system: Can produce block, pillow or granular products.

In addition, we also provide:

- SBC hot melt adhesive formula support

- Installation and technical training

- Global after-sales service network

Why choose JCT?

- 20+ years of equipment manufacturing experience

- Exported to many countries around the world, reliable quality

- Suppot OEM/customized solutions

- Engineers can be stationed overseas for installation and technical support

- Provide formula and process guidance to help you quickly put into production

JCT

JCT  2025-10-14

2025-10-14