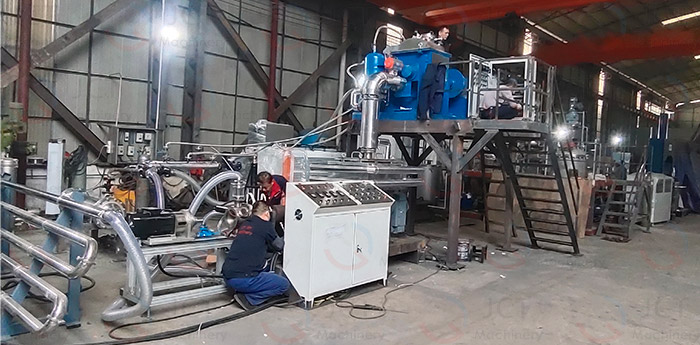

Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2026-01-08

2026-01-08

Most hot melt glue is currently produced in batches; continuous production is mainly used for standardized hot melt glue with stable formulas and large production volumes.

From the customer's long-term operational prespective:

Intermittent operation is safer, more stable, and offers better risk control.

Hot melt glue production can be carried out using either continuous or intermittent processes. Currnetly, the industry mainly uses intermittent production because it is more suitable for producing a wide variety of hot melt glue due to its strong formula adaptability, stable operation, adn low investment risk. Continuous production is mainly used for standardized products with fixed formulas and large production volumes.