Equipment level: Improve mixing, melting and cooling efficiency

Choose high-efficiency mixing equipment

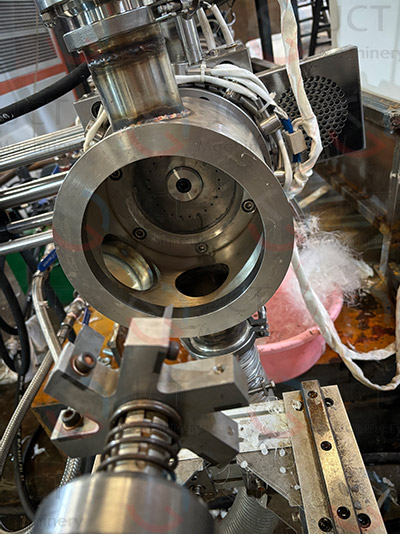

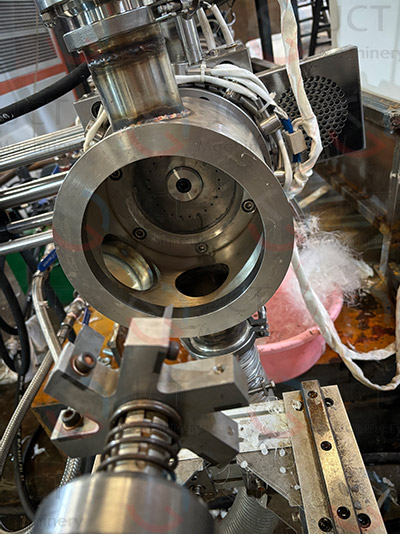

- Sigma mixer: Provides powerful shear and kneading forces, achieving 30-50% higher mixing efficiency than conventional stirred tanks.

- Optimized blade structure: ∑-shaped blade can be customized based on material viscosity, improving mixing uniformity and reducing dead spots.

- Vacuum degassing: Degassing while stirring shortens mixing time and improves product quality.

Improve heating efficiency

- Use thermal oil circulation heating system or electric heating jacket with a temperature control module to achieve rapid and uniform heating.

- Use high thermal conductivity material (such as SS304/316 with polished interior) to reduce energy loss.

Optimized discharging and pelletzing equipment

- Continuous extrusion pelletizing systems replace intermittent discharging, enabling continuous production.

- Underwater pelletizing or cooling belt+pelletizer combination provides fast cooling and stable pelletizing.

- Automated cutting systems reduce manual intervention.

Process level: Optimize formula and production process

- Pre-melt or pre-mix some raw materials: Pre-melting or pre-mixing wax or resin components can reduce the main kettle heating and mixing time.

- Optimize the addition sequence: Adjusting the addition sequence based on the melting points and compatibility of the materials can avoid repeated heating and shorten the reaction time.

- Control material viscosity: High viscosity can reduce mixing and pumping speeds. Adjust the resin ratio or add a flow improver.

- Switching to continuous production process: Traditional batch production is inefficient, so modern hot melt glue factory is moving towards:

- Continuous feeding+continuous extrusion

- Dynamic mixing+online filtration+online pelletizing

Raw material level: Choose an easy-to-process system

- Select low-melting-point, high-flow resins (such as EVA, APAO and TPR).

- Control filler and additive particle size to reduce agglomeration and improve mixing fluidity.

- Use low-volatility raw materials to reduce vacuum pumping and degassing time.

Automation and intellignet control

PLC+touchscreen automation control system

- Automatically controls temperature, mixing speed, feed rate and discharge speed.

- Can store recipe parameters for quick product switching.

- Precise temperature control reduces manual intervention, improving stability and dafety.

Robotic automatic feeding system

- Enables continuous and precise addition of raw materials, eliminating manual interruptions.

- Improves feeding accuracy and speed.

- Reduces dust and human contact, improving environmental safety.

Production line informationization

- Real-time monitoring of output, energy consumption, and equipment operating status enables production data analysis and efficiency optimization.

JCT provide hot melt glue production line, including a full set of equipment, formula, installation and usage tutorial, and maintenance. The formula purchased from JCT support permanent free upgrades. We can also help you to find the raw material suppliers.

Feel free to contact us if you are interested in hot melt glue production line turnkey project: +86-181 3837 3963 (Whatsapp, Wechat) or jctmixing@outlook.com.

JCT

JCT  2025-10-21

2025-10-21