Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

| Industry | Application |

| Packaging industry | Bottle and carton sealing |

| Sanitary products | Structural adhesive for diapers and sanitary napkins |

| Label industry | Quick labeling |

| Book binding | Book spine adhesive |

| Automobile manufacturing | Wire harness fixing, decorative parts bonding |

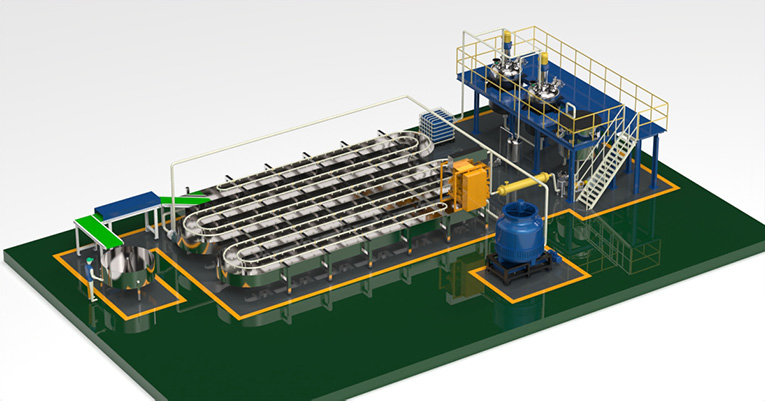

1. Reactor / Sigma mixer

Mix molten resin, additives, tackifiers, etc. evenly.

2. Filtration system

Remove impurities and protect the back-end metering and die head.

3. Metering pump + Melt pipe system

Control flow to ensure stable discharge.

4. Pillow hot melt glue packaging machine

Automatically wrap with PE film and cut to a fixed length, and the weight of each piece of hot melt glue is consistent.

5. Conveyor belt + Water cooling system

Quickly cool the hot melt glue pillow and transfer it.

1. Can hot melt glue of different viscosities be produced?

Pillow hot melt glue production line equipment designed and manufactured by JCT is suitable for colloids with different viscosities. Reactor is used for low viscosity and sigma mixer is used for high viscosity.

2. Is the coating meltable? Is it polluting to customers?

The coating is a hot-melt PE film that can be used with hot melt glue without tearing it off.

3. Is it environmentally friendly?

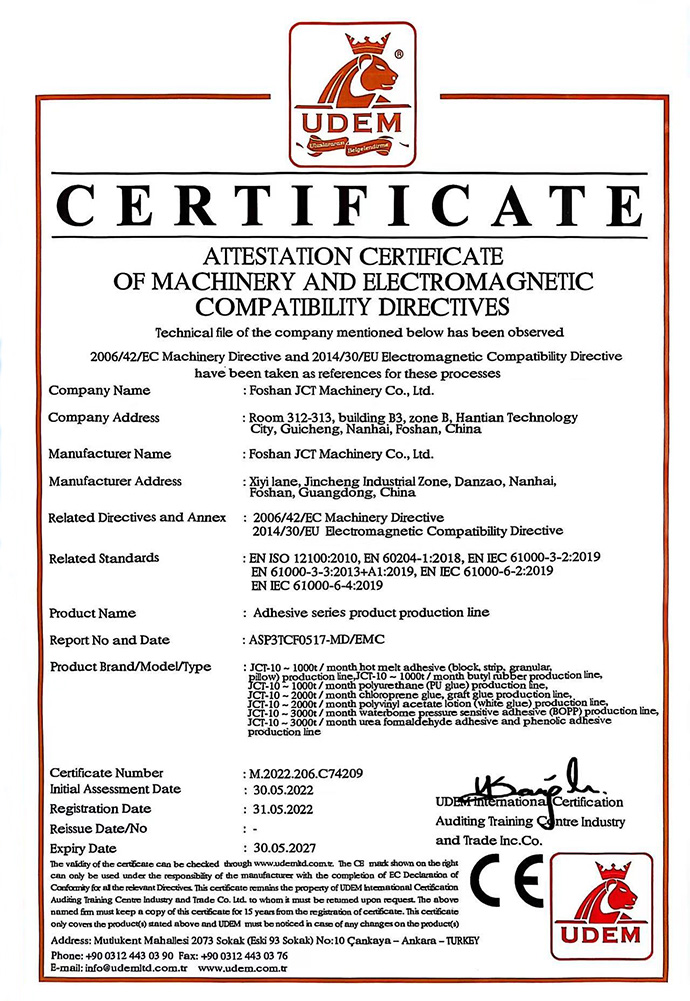

The pillow hot melt glue production line adopts a closed design from raw material mixing to coating molding, with extremely low VOC, and supports CE certification requirements (or other customer-specified certifications).