Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

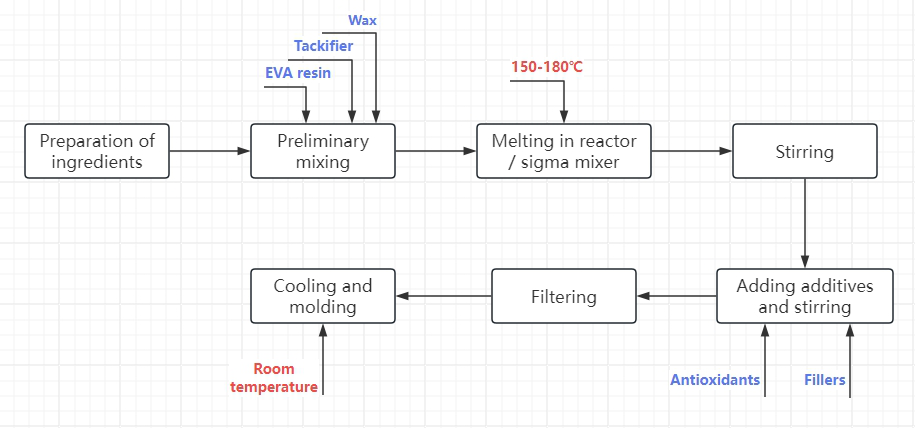

What is pressure sensitive adhesive? Pressure sensitive adhesive (PSA) is a hot melt adhesive that maintains permanent viscosity at room temperature. It can be coated on the surface of the substrate after heating and melting, and still maintains a cert

Product Specification:Pressure sensitive adhesive (PSA) is a hot melt adhesive that maintains permanent viscosity at room temperature. It can be coated on the surface of the substrate after heating and melting, and still maintains a certain viscosity after cooling. It can achieve bonding under low pressure and can be repeatedly pasted and peeled.

| Ingredients | Functions |

| Base polymer (such as SIS, SBS, SEBS, EVA) | Provides viscosity, elasticity and weather resistance |

| Tackifying resin (such as C5/C9 petroleum resin) | Increases initial adhesion and improves bonding strength |

| Softener/Plasticizer (such as liquid tackifying resin, mineral oil) | Reduces viscosity and improves fluidity |

| Antioixidant | Increases thermal stability and prevent oxidative degradation |

| Filler (such as calcium carbonate) | Reduce cost and adjust viscosity |

Q: How to produce pressure sensitive adhesives of different qualities?

A: JCT provides you with high-quality equipments to ensure that you can produce high-quality pressure sensitive adhesives.

To obtain pressure sensitive adhesive with different performance characteristics, the formula of the pressure sensitive adhesive needs to be adjusted:

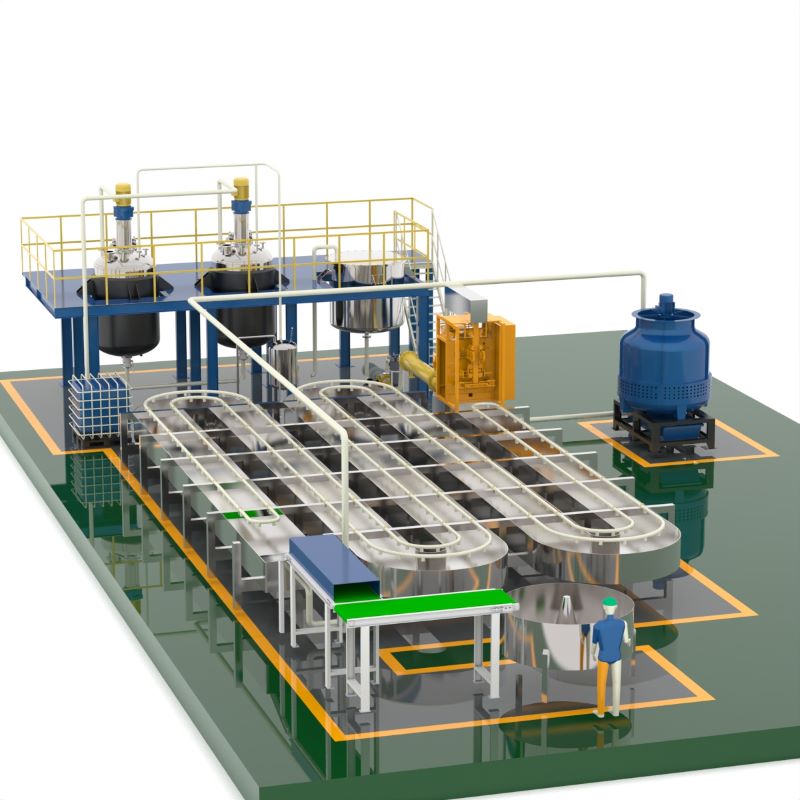

1. Reactor (or sigma mixer)

2. Storage tank

3. Vacuum system

4. Filtration system

5. Chiller system

6. Packaging machine

7. Cooling water tank

| Comparision Items | Pillow PSA Production Line | Bulk PSA Production Line |

| Molding Method | The melt is extruded through the die head and then inflated and molded | The melt is extruded and then calendered or cast |

| Product Form | Pillow-shaped (similar to a small inflatable pillow) | Solid cube or reactangular block |

| Cooling System | Water cooling | Water cooling or metal plate conduction cooling (rapid solidification) |

Please provide your requested item product name and request details as like box style, material, dimensions, color and logo request, we can help to find out best packing solution.