Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT Machinery has 20+ year experience of hot melt label glue production line equipment manufacturing.

Product Specification:Provide one-stop service of equipment + formula + process training to help break through the technical barriers of imported hot melt label glue!

Consult now: +86-181 3837 3963 (Whatsapp, Wechat) or jctmixing@outlook.com.

Support trial production with customer supplied materials to verify equipment adaptability!

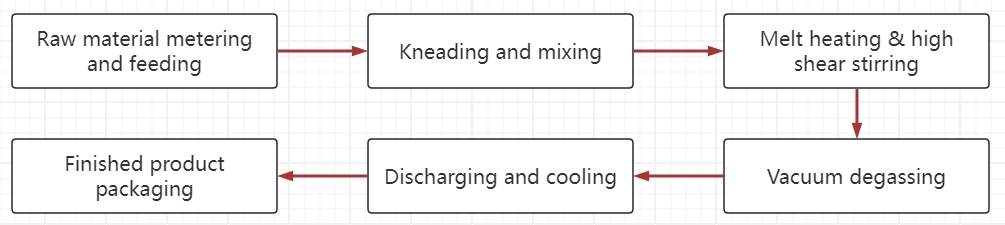

Hot melt label glue is a kind of adhesive that does not require solvents or water, is solid at room temperature, can melt and flow after heating, and quickly cools and solidifies after coating. It has certain initial adhesion and peeling properties.

Hot melt label glue is widely used in various self-adhesive labels, express delivery orders, product barcodes, bottle labels, food packaging and other label fields.

| Component | Function |

| Polymer (such as EVA, SBC) | Provides adhesion and flexibility |

| Tackifying resin (such as C5/C9 petroleum resin) | Enhances initial adhesion and peeling strength |

| Plasticizer/oil agent | Adjusts viscosity and fluidity |

| Antioxidant, stabilizer | Enhances aging resistance |

**For reference only, may be slightly adjusted according to different cold patch/hot patch/removable formulas.

1. Equipment models range from laboratory 5L (sigma mixer) to 2000+L (sigma mixer) or 80,000L (reactor).

2. Provide complete turnkey project (equipment + formula + guidance),

3. Exported to many countries, suitable for EVA, SBC, APAO system hot melt glue.

4. Production line design supports different viscosity and col stick/removable/permanent labels.

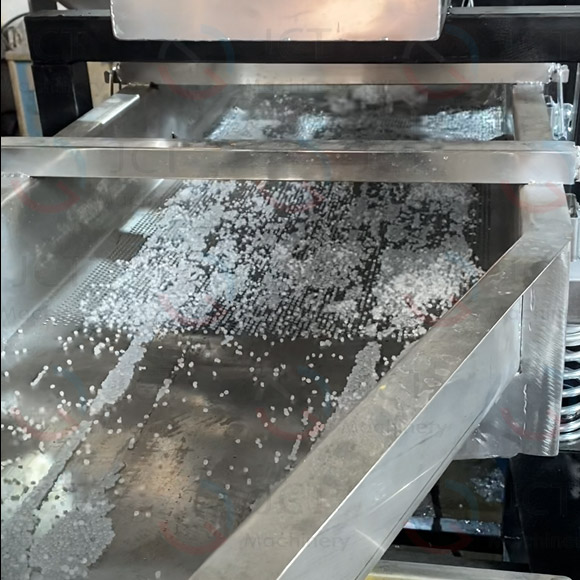

5. Optional mold cooling discharge, granulation discharge, pillow packaging discharge.

6. Permanently support free formula upgrades to help customers improve their market competitiveness.

Please provide your requested item product name and request details as like box style, material, dimensions, color and logo request, we can help to find out best packing solution.