Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

Hot melt coating adhesive is a type of hot melt glue specifically designed for use in coating equipment (such as coating machines and laminating machines).

Product Specification:Hot melt coating adhesive is a type of adhesive that is heated and melted from a solid state, then eveny applied to substrate such as paper, film, fabric, aluminum foil, and foam using methods such as blade coating, roller coating, spray coating and dispensing. Upon cooling, it forms a uniform adhesive layer.

It features 100% solid content, is solvent free, cures quickly, and is environmentally friendly and odorless. It is an important type of adhesive used in modern automated packaging, furniture, hygiene products, textiles, and automotive interior industries.

| Equipment | Function |

| Reactor | Heat and stir the raw materials to bring hot melt glue to a fluid state and maintain a stable viscosity |

| Filtration system | Remove impurities to prevent clogging of the nozzle or coating head and ensure uniform coating |

| Gear pump/metering pump | Precisely control the coating amount to improve product stability |

| Coating head | Select the appropriate type of coating head based on the material, such as scraper type, comma scraper or slot die |

| Coating machine body | Includes unwinding, web guiding system, tension control, coating section and cooling section |

| Cooling system | Typically uses cooling rollers, air cooling, or water cooling to quickly solidify the adhesive layer |

| Winding system | Uses constant tension winding to ensure the rolled material is flat and wrinkle-free |

As a hot melt glue production line equipment manufacturer, we provide our customers with:

1. Complete production line design

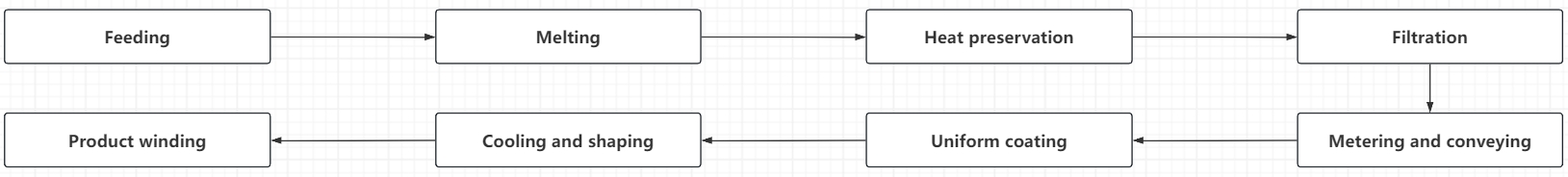

A complete turnkey project from melting, filtering, and metering to coating, laminating, and winding.

2. Customized coating head structures based on materials and applications

Slot die, comma blade, and gravure roller coating heads are all customizable.

3. Factory planning + process guidance + on-site installation and commissioning

Helping customers establish a hot melt coating adhesive factory from scratch.

4. Experienced engineering team

Accumulated numerous successful cases in the fields of labels, medical coatings and composite materials.

5. Provision of formula references and process parameters

Helping customers quickly put into production.

Please provide your requested item product name and request details as like box style, material, dimensions, color and logo request, we can help to find out best packing solution.