Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

1. Heat resistance

For components such as headliners and door panel seals that must withstand high vehicle temperatures (up to 105℃), PO/PA hot melt glue or PUR hot melt glue are recommended.

2. Flexibility and resilience

For coverings requiring a high tactile feel (such as headliners and soft-touch panels), EVA hot melt glue or modified PO is required to ensure softness and resist cracking.

3. Aging and UV resistance

For interiors exposed to long-term light adn heat cycles, PUR hot melt glue and PA hot melt glye offer the best long-term performance.

4. Low odor and low volatility

For automotive interiors with stringent requirements for volatile organic compounds (VOCs) and odor, low-VOC PO hot melt glye or formaldehyde-free EVA hot melt glue are more suitable.

5. Automation compatibility

All systems must meet the requirements for quick-drying (opening time <3 seconds) during spraying/applying to accommodate high speed dispensing and lamination cycles in the workshop.

With the rapid development of the automotive industry and the increasing global demand for lightweight, environmentally friendly, and efficient automotive manufacturing technologies, the application of hot melt glue in the bonding of automotive interior components has also gradually expanded. Whether bonding door panels, ceilings, instrument panels, carpets, or fabrics, foam, or plastic parts, hot melt glue have become a widely adopted adhesive solution by automakers due to their excellent adhesion, fast curing, and environmental performance.

1. Large market demand and stable growth

The continued expansion of the automotive industry has driven a surge in the use of adhesive materials, particularly in developing and automobile-exporting countries such as China, India, Southeast Asia and Russia.

2. High value-added products and quick returns

Hot melt glue specifically for automotive interiors are generally high-performance glue with high profit margins and strong customer loyalty. Once established in the OEM or interior parts supply chain, long-term partnerships can be established.

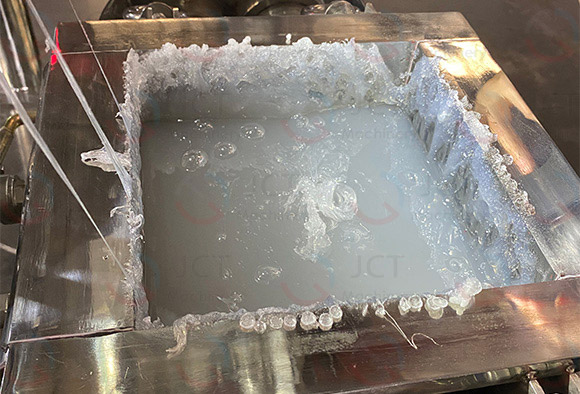

3. Mature equipment with modular customizability

JCT's hot melt glue production line can be customized to meet formula requirements, including kneading systems, reactors, cooling and granulation systems, and packaging systems. They support a variety of packaging formats, including granules, blocks and pillows, allowing customers to flexibly adapt to different markets.

4. Turnkey project, worry-free technology

JCT not only provides a complete set of equipment but also offers one-stop services, including hot melt glue formula, personnel training, process guidance, installation and commissioning, helping customers quickly start production and successfully enter the automotive hot melt glue market.