Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

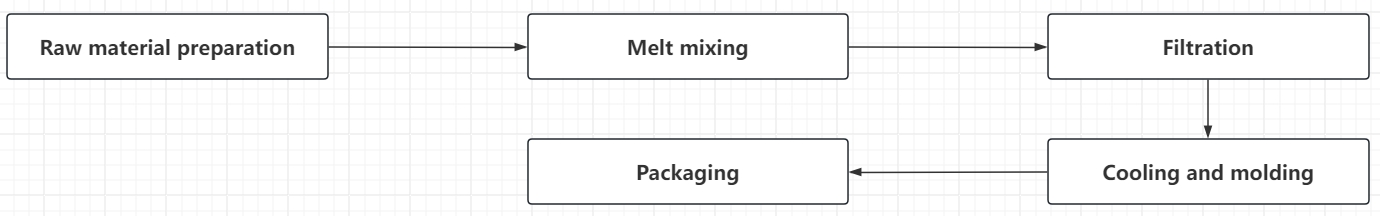

The global hot melt glue market continues to grow, with a CAGR of approximately 5%-6%. Demand is robust in sectors such as packaging, automotive, electronics, and hygiene products. Investing in hot melt glue production line not only delivers rapid returns but also aligns with energy conservation, emission reduction, and green manufacturing trends.

We can help you produce different types of hot melt glue!

Global hot melt glue market is growing steadily, with packaging and e-commerce driving the largest demand. With a wide variety of hot melt glue to meet various needs, the hot melt glue market can achieve sustainable growth under the circumstances of vigorous development of various industries, limited domestic market competition and huge export potential.

The factory location directly impacts the success of the project and must be chosen carefully. We will design the location of hot melt glue production line equipment free of charge according to the factory area provided by the customer. Considering future expansion, it is recommended that the factory reserce enough space in advance.

The successful implementation and sustainability of a project require a dedicated team of chemical engineers, workers, managers, and technicians.

JCT welcomes customers to visit our factory to learn about hot melt glue formulations and manufacturing procedures. We also support the dispatch of chemical engineers to provide on-site production training.

Hot melt glue formulas purchased from us come with permanent, free formula upgrades. Upon delivery of the equipment, we provide installation and operating instructions.

| Immature or unstable formula | JCT can provide formula guidance and process optimization support |

| Raw material prices fluctuate | Lont-term partnerships with suppliers ensure advance stockpiling. JCT can also assist clients in sourcing raw materials |

| Global market is highly competitive | We recommend that clients focus on specific areas (suhc as packaging, automotive and electronics) to achieve differentiated positioning |

| Evolving environmental policies and requirements | Our equipment is equipped with an environmentally friendly recycling system and continuously monitors and complies with industrial waste disposal standards |

If you are interested in hot melt glue production line turnkey project, feel free to chat with us: +86-181 3837 3963 (Whatsapp, Wechat) or jctmixing@outlook.com.