Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

1. Base Polymer

Differences in molecular weight, branching degree, and polarity of different polymers result in different viscosities.

High molecular weight → high viscosity. Low molecular weight → low viscosity.

2. Tackifying Resin

The higher the tackifier dosage, the softer the colloid becomes at low temperatures, and the viscosity decreases accordingly.

However, the softening point and polarity of the resin also affect the viscosity of the system.

3. Waxes and Plasticizers

Waxes and plasticizers can reduce the viscosity of the system and improve fluidity.

Adding too much can reduce bond strength and heat resistance.

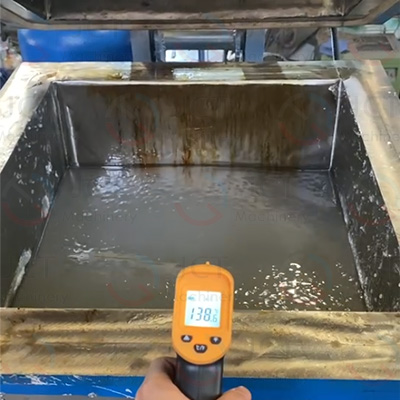

Increasing temperature → decreasing viscosity (hot melt adhesive flows more easily when heated).

Excessively high application temperatures may cause the adhesive to be too thin, penetrate too deeply, or even burn.

Excessively low temperatures increase the adhesive's viscosity, making application difficult and resulting in poor wetting.

Hot melt glue generally behave as non-Newtonian fluids (pseudoplastic fluids), meaning:

Prolonged heating of hot melt glue can cause oxidation and molecular chain degradation, resulting in viscosity changes:

Humidity: Some polar hot melt glue (such as polyamides) absorb moisture, causing viscosity to increase.

Fillers: Adding fillers such as silica and calcium carbonate increases system viscosity.

As a professional hot melt glue production line turnkey project provider, JCT uses equipment to stably achieve and maintain consistency in production of the "theoretical viscosity" determined by the formula through precise temperature control + controllable shear/residence time + stable feeding + online detection and closed-loop control.