Best Hot Melt Glue Production Line Equipment Manufacturer

Tel: +8618138373963 | jctmixing@outlook.com

JCT

JCT  2025-10-14

2025-10-14

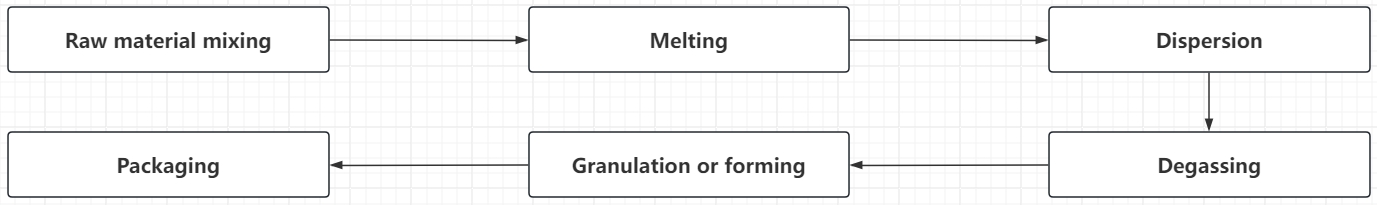

Hot melt glue is mainly divided into EVA hot melt glue, PO hot melt glue, SBS/SEBS hot melt pressure-sensitive adhesives, PUR hot melt glue, etc. according to raw material type and application. Different types of hot melt glue production lines have both similarities and differences in equipment configuration, process requirements and application areas.

Sigma mixer (for high-viscosity materials)

Reactor (heating, reaction, mixing)

Extruder (for granulation or strand forming)

Cooling and packaging equipment

Both systems are solvent-free, with low VOC emissions and are environmentally friendly.

Designs are available, ranging from laboratory scale (5L) to large scale industrial production line.

1. EVA hot melt glue production line

Raw Materials: Ethylene-vinyl acetate copolymer (EVA), tackifying resin, paraffin wax/microcrystalline wax, etc.

Process Characteristics: Relatively simple formula, stable process.

Key Equipment: Sigma mixer / reactor + extruder pelletizer.

Applications: Packaging, labeling, bookbinding, woodworking.

2. PO hot melt glue production line

Raw Materials: Polyolefin (such as polypropylene), tackifier, antioxidant.

Process Characteristics: Requires high processing temperature, good melt flowability.

Key Equipment: High-temperature resistant extruder, vacuum degassing system.

Applications: Hygiene products (diapers, sanitary napkins), non-woven fabric lamination.

3. SES/SEBS hot melt pressure sensitive adhesive production line

Raw Materials: Styrene-butadiene-styrene (SBS), Styrene-ethylene-butylene-styrene (SEBS), tackifying resin, oil.

Process Characteristics: High-viscosity system requires strong dispersion and vacuum degassing.

Key Equipment: High-powered sigma mixer.

Applications: Label tapes, medical patches, protective films.

4. PUR hot melt glue production line

Raw Materials: Isocyanate-terminated polyurethane prepolymer.

Process Characteristics: Requires a water- and oxygen-free environment to prevent premature reaction.

Key Equipment: Sigma mixer/reactor, nitrogen protection system, solvent-free metering pump.

Applications: Automotive interiors, electronic assembly, wood composites, and high-end packaging.